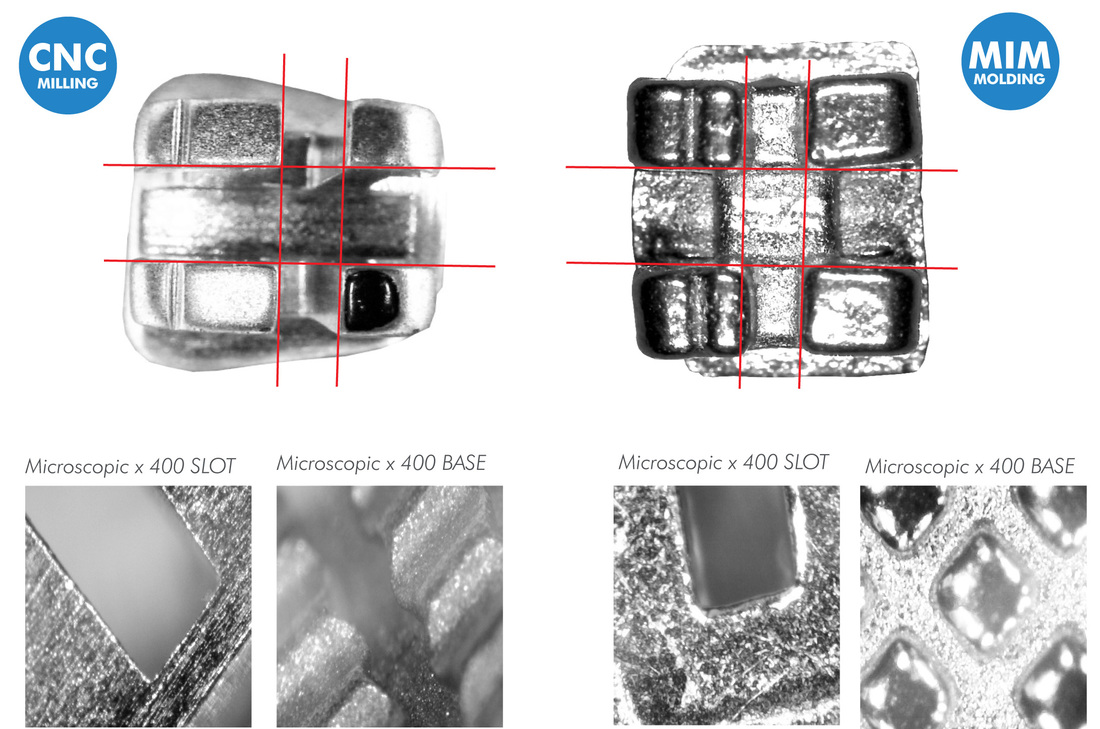

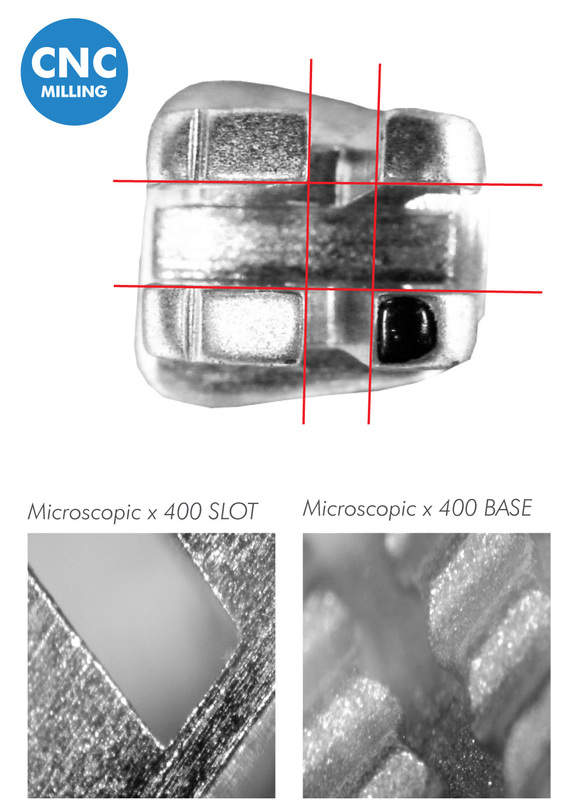

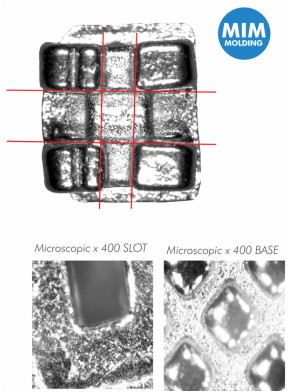

Sometimes you just have to let the picture do the talking!

unaltered microscopic photos x 200

|

What does this mean to you the orthodontist?

|

3D CAD_CAM CNC Milling by Adenta

3D CAD-CAM: Computer Aided Design and Computer Aided Manufacturing: CAD is the use of computer technology for design and design documentation. CAD/CAM applications are used to both design a product and program manufacturing processes, specifically, CNC machining. CAM software uses the models and assemblies created in CAD software to generate tool paths that drive the machines that turn the designs into physical parts. CNC: Computer Numerical Control: Computers control the machine tools: Everything that an operator would be required to do with conventional machine tools is programmable with CNC machines. This precise computer control of positioning, velocity, feed rate, location, and speed produces highly precise results, reproducible as human fatigue and error are removed. |

The disadvantages of MIM Metal Injection Molding

|

The process steps involve combining metal powders with wax and plastic binders to produce the ‘feedstock’ mix that is injected as a liquid into a hollow mold using plastic injection molding machines.

The ‘green part’ is cooled and de-molded in the plastic molding machine. Next, a portion of the binder material is removed using solvent, thermal furnaces, catalytic process, or a combination of methods. The resulting, fragile and porous (2-4% “air”) part, in a condition called “brown” stage, requires the metal to be condensed in a furnace process called Sintering. MIM parts are sintered at temperatures nearly high enough to melt the entire metal part outright (up to 1450 degrees Celsius), at which the metal particle surfaces bind together to result in a final, 96-98% solid density.

|

|

|

|

Mailing address: Germany - Head Office

Adenta GmbH Gutenbergstrasse 9, D-82205 Gilching Germany | T. +49 8105-73436-0 | F. +49 8105-73436-22 | Email. [email protected]

Adenta GmbH Gutenbergstrasse 9, D-82205 Gilching Germany | T. +49 8105-73436-0 | F. +49 8105-73436-22 | Email. [email protected]