CAD/CAM CNC milled brackets....high quality accuracy, high quality results

|

CAD/CAM stands for Computer-aided design/computer-aided manufacturing.

The CAD/CAM technology allows our engineers to use this system both for designing our brackets and for controlling the manufacturing systems. The CNC milling process are the milling machines the computers program to reproduce over and over an identical velocity, feed, location and speed without any varying components, including human fatigue. This manufacturing method is without a doubt the most precise and accurate method of manufacturing small metal parts, its proven record speaks for itself. |

CAD/CAM CNC Milled brackets...accurate to within a thousandth of an inch - what does this mean to you?

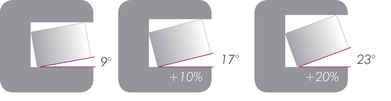

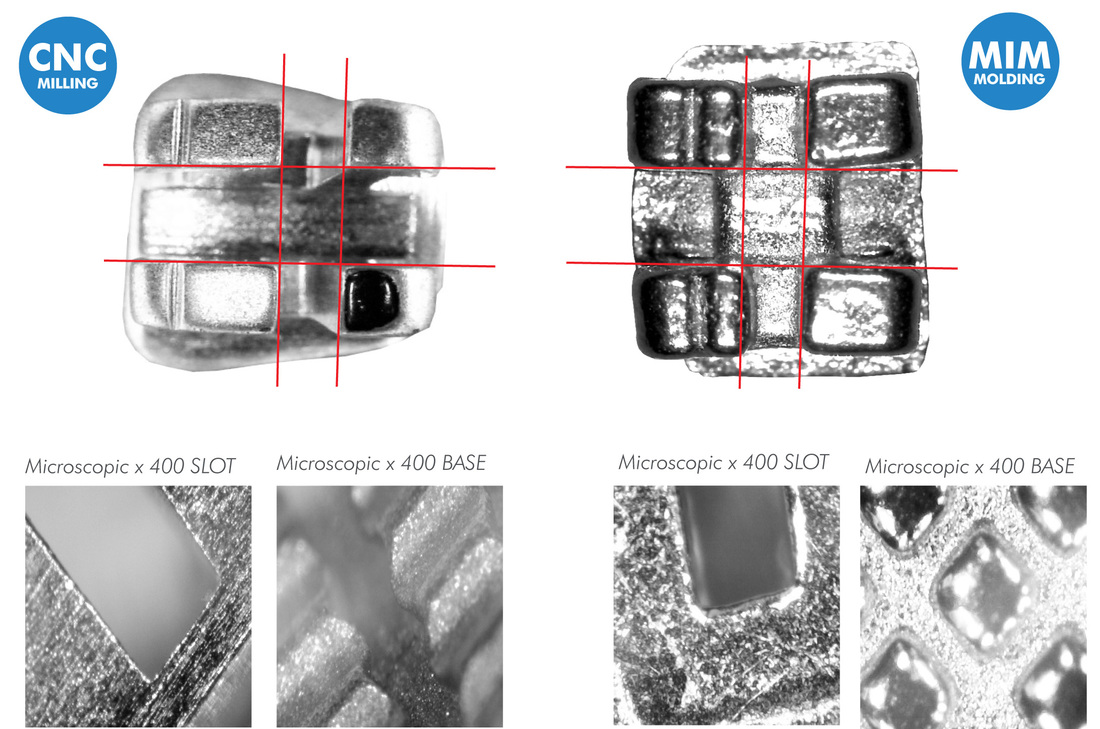

The bracket system will only reproduce their prescription when slots and wires fit intimately together to produce the three-dimensional tooth moving forces needed. Inaccurate slots and inaccurate geometry will result in incomplete transmission of the bracket prescription.

- Ultra precise slot delivers a pure and accurate transmission of the prescription to finish your cases without any further detailing.

- 100% pure milled stainless steel for a strong bracket wing that can withstand the rigors of orthodontic treatment.Sandblasted mechanical undercuts to reduce those pesky lost bracket appointments.

- Smooth flat finish to reduce friction for fast and efficient tooth movement and reduce the accumulation of plaque.

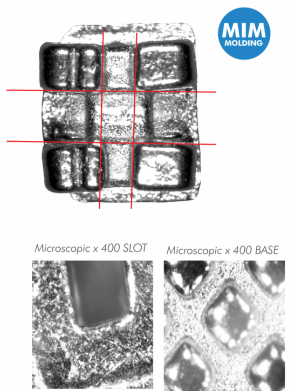

Sometimes we just let the picture do the talking!Unaltered microscopic photos of both a CNC milled bracket and the most popular method of manufactuing MIM Molding...a picture is worth a thousand words.

|

The disadvantages of MIM Metal Injection Molding

|

The process steps involve combining metal powders with wax and plastic binders to produce the ‘feedstock’ mix that is injected as a liquid into a hollow mold using plastic injection molding machines.

The ‘green part’ is cooled and de-molded in the plastic molding machine. Next, a portion of the binder material is removed using solvent, thermal furnaces, catalytic process, or a combination of methods. The resulting, fragile and porous (2-4% “air”) part, in a condition called “brown” stage, requires the metal to be condensed in a furnace process called Sintering. MIM parts are sintered at temperatures nearly high enough to melt the entire metal part outright (up to 1450 degrees Celsius), at which the metal particle surfaces bind together to result in a final, 96-98% solid density.

|

Sign up for our Newsletter!

|

|

|

Mailing address: Germany - Head Office

Adenta GmbH Gutenbergstrasse 9, D-82205 Gilching Germany | T. +49 8105-73436-0 | F. +49 8105-73436-22 | Email. [email protected]

Adenta GmbH Gutenbergstrasse 9, D-82205 Gilching Germany | T. +49 8105-73436-0 | F. +49 8105-73436-22 | Email. [email protected]