Choosing the best wire for the appliation

FLEXADENT™

|

NiTi -approximately 55% Ni and 45% Ti:

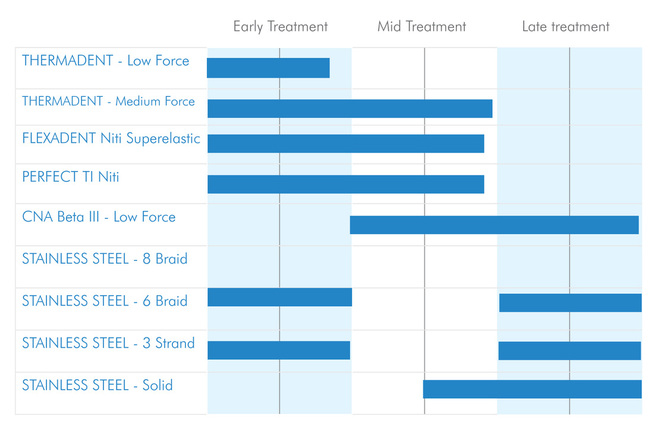

FLEXADENT™ - Ideal for alignment and leveling in early to mid-stages of treatment. All NiTi wires exhibit a unique “Superelastic” behavior. Superelastic behavior provides: • Light to moderate, consistent forces. • Responsiveness to chilling. • Near consistent force over a long activation period. • Greater patient comfort over Stainless Steel wires. • Excellent resiliency, resulting in high resistance to permanent set. • High flexibility. • Leveling, torque, and rotation can be addressed simultaneously early in treatment. No need to treat each of these individually, as is the case if using Stainless Steel wires. |

THERMADENT™

|

In addition, Nickel Titanium wire may also demonstrate a heat-activated "Shape Memory" effect produced through a tightly controlled manufacturing process.

THERMADENT™ Heat Activated wires are shape memory, heat-activated wires. Shape memory properties exhibited by heat-activated, or thermal, Nickel Titanium wires: • Superb flexibility at room temperature, allowing for even easier ligation. Soft in the hand. • Very responsive to chilling. • Gentle forces are initiated by intraoral heat and remain consistent throughout treatment. • Noticeably more comfortable for the patient due to low forces. • Allows for patient to control discomfort with cold water rinses. |

PERFECT-TI™

|

NiTi -approximately 55% Ni and 45% Ti:

Your customers will love the efficiency of our PERFECT-Ti™ superelastic premium wires! adenta developed this ultra smooth, hard black surface nickel titanium wire engineered specifically for reduced friction and efficient tooth movement. • 30% less friction than traditional Nickel Titanium wire provides improved sliding mechanics. • Our highest force Superelastic NiTi wire. • Hard surface is an integral part of the wire; not a coating. • Black color nearly indistinguishable from other wires when in the mouth. • Very resilient. |

TRIDENT™

|

A titanium molybdenum wire composed of 79% Ti, 11% Mo, 6% Zr, and 4% Sn:

The characteristics of our custom designed, nickel-free Beta III Titanium wire make this perfect for use in mid- to late stages of treatment where space closure, rotation, and proper molar relationship are the goal. • Nickel-free! Eliminates treatment concern of nickel sensitivity in patients. • Excellent formability allows easy fabrication of loops and bends for space closure and tooth movement. • Easily accepts 1st and 2nd order bends for tipping and aligning. • Very good resiliency as compared to Stainless Steel. • Approximately half the tooth-moving force of Stainless Steel. • Excellent finishing wire. • Retainer and appliance fabrication is easy with our Beta III CNA™ 14“ lengths • CNA Beta III significantly outperforms TMA Beta III and easily accepts 1st and 2nd order bends without breaking issues. |

DURADENT™

|

Our archwires are manufactured from medical grade 304V Stainless Steel material (70% Fe, 19% Cr, 9% Ni, 1.5% Mn, 0.5% Si). These archwires can be used throughout treatment but are best suited for mid - to late stages of treatment.

• Superior surface finish. • Higher force and limited resiliency as compared with Beta III CNA™ wire. • Forces drop quickly; best suited as a finishing wire. • Easy to bend. • Greater patient discomfort when used in early treatment stages. |

TWISTADENT™

|

Adenta’s three types of multi-strand wires made of medical grade Type 302SS (71% Fe, 18% Cr, 9% Ni, 1% Mn, 0.5% Si) are well suited for early stages of treatment as well as the finishing stage of detailing and retention. Lower forces and better resiliency than solid Stainless Steel.

• TWISTADENT™ 3-strand (twisted) wire provides moderate forces and limited flexibility. • TWISTADENT™ Coax (6-strand) wire provides lighter to moderate forces and slightly better resiliency than 3-strand. • TWISTADENT™ 8-Braid wire provides the lightest forces of the multi-strand Stainless Steel wires, with relatively good resiliency. |

BEAUTYDENT™

|

Over the past few years we have made significant advances in the manufacturing process of our new BEAUTYDENT™ cosmetic archwire. This new manufacturing process insures that your cosmetic wire maintains its stain resistant coating, without the complication of the "peel-off" effect.

|

|

|

|

Mailing address: Germany - Head Office

Adenta GmbH Gutenbergstrasse 9, D-82205 Gilching Germany | T. +49 8105-73436-0 | F. +49 8105-73436-22 | Email. [email protected]

Adenta GmbH Gutenbergstrasse 9, D-82205 Gilching Germany | T. +49 8105-73436-0 | F. +49 8105-73436-22 | Email. [email protected]